JIANGMENSTRONGINTELLIGENTTECHNOLOGYCO.LTD. -Pad Printing Plate (Mr. Lin +8613702920751 Mr. Huang +8613676182229)

There are issues with the production of Pad Printing Plate

Common problems in the production process of Pad Printing Plate include the detachment or cracking of photosensitive paste during development, incomplete pattern display, and detachment of photosensitive paste. These problems are usually caused by long drying time or high temperature, insufficient exposure time, uneven application of photosensitive paste, high concentration of developer, long development time, deterioration of photosensitive paste, or other harmful light invasion

1.

solution

Adjust the baking time and temperature: Ensure that the baking time is moderate and the temperature is not too high.

Ensure sufficient exposure time: The exposure time should be sufficient to ensure that the photosensitive paste is completely cured.

Apply photosensitive paste evenly: The photosensitive paste should be applied evenly to avoid being too thick or too thin.

Adjust developer concentration and time: The developer concentration should be moderate, and the development time should not be too long.

Check the quality of the photosensitive paste: Ensure good quality of the photosensitive paste and avoid using deteriorated photosensitive paste.

Production process of Pad Printing Plate

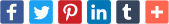

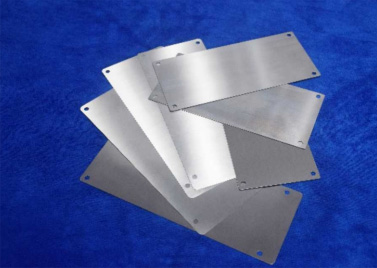

Cleaning steel plate: Use transfer printing steel plate to treat water and clean the greasy surface of the plate.

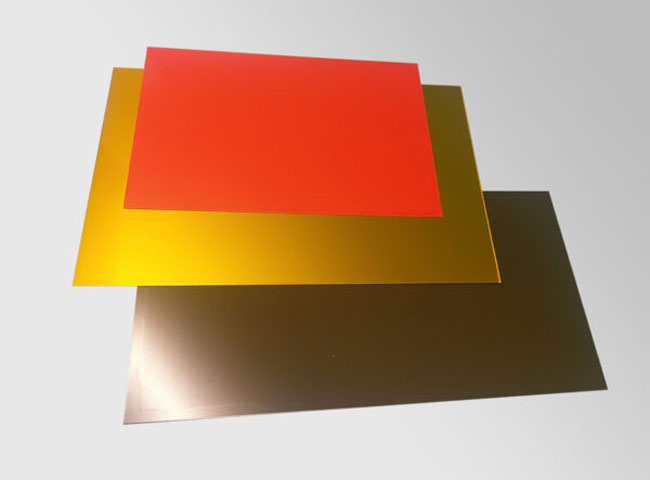

Apply photosensitive paste: Drop two drops of photosensitive paste onto a pure white surface and let it dry naturally.

Exposure: Expose in the dark for 90-120 seconds to ensure that the photosensitive paste is cured.

Development: Develop with developer to ensure clear patterns