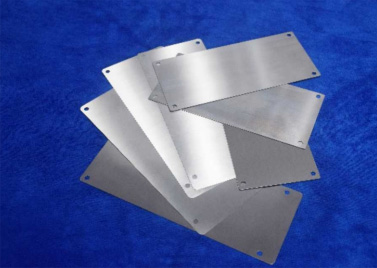

JIANGMENSTRONGINTELLIGENTTECHNOLOGYCO.LTD. -Pad Printing Plate (Mr. Lin +8613702920751 Mr. Huang +8613676182229)

Process flow of transfer printing steel plate production

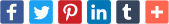

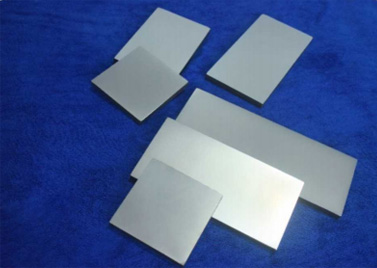

The transfer printing steel plate industry often talks about how it is produced. Our goal is to accurately etch patterns onto the surface of steel plates through photochemical and corrosion techniques Today, I will take you to learn about the process of making transfer printing steel plates We need a blank steel plate to be completed under professional equipment, Firstly, prepare the film, as the accuracy of the pattern will directly affect the final effect, so it is necessary to check whether the film has impurities or damage. Secondly, cleaning and pre-treatment of steel plates. In order to thoroughly remove oil and dust from the surface of the steel plate, it is necessary to meet the “absolute cleanliness” standard, usually using Tianna water or specialized cleaning agents. Thirdly, sizing, evenly covering the surface of the steel plate with photosensitive adhesive, can be achieved by centrifugal coating (more uniform) or manual coating using a spin coater. After coating, it needs to be placed upside down in a dust-free dark box. Fourth, baking can be done at room temperature for 12 hours or in an industrial oven at 150 ℃ for 15 minutes Fifth, exposure: Fix the designed film (including the pattern) in the designated position on the steel plate with transparent tape, and use a UV exposure machine for a typical exposure time of 30 seconds to one minute Sixth, highlight by rinsing with developing water, i.e. sodium carbonate solution, the unexposed part of the photosensitive adhesive will dissolve and expose the steel plate. Repeat the development until the pattern is clear Seventh, fill the sand hole. After drying the water, use adhesive tape to stick it to the position that does not need to be engraved with candles, and then fill the sand hole Eighth, corrosion, pour in candle etching water for etching time of 1.8 minutes Ninth, remove the adhesive, tear off the adhesive paper, use plate washing water (such as Tenna water) to remove residual photosensitive adhesive, and complete the plate making process